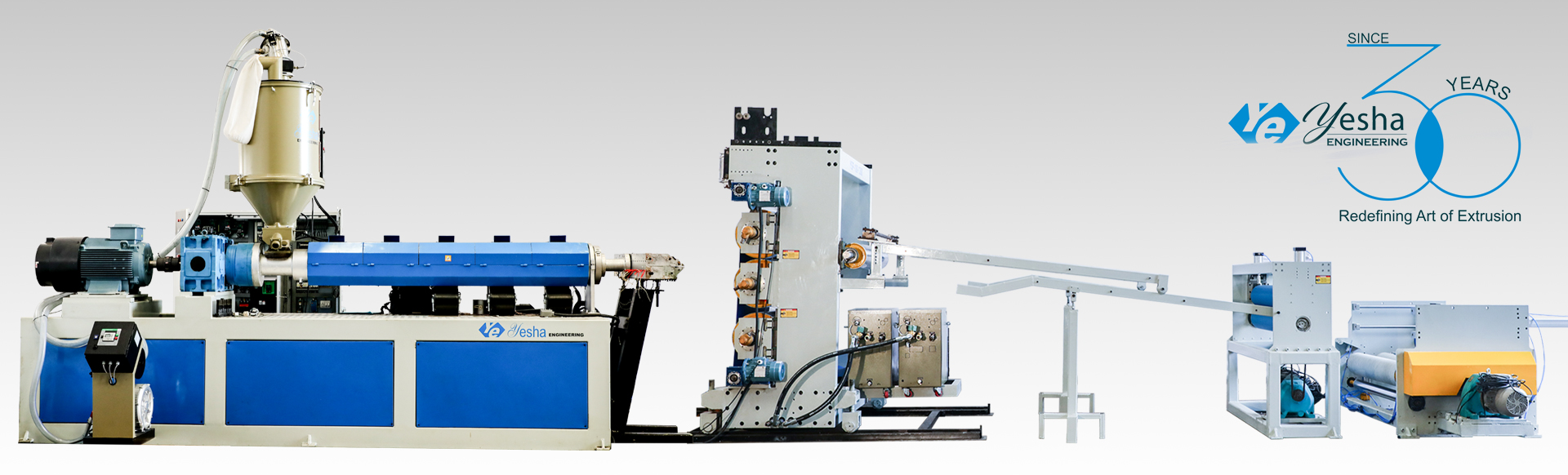

Liner Film Extrusion Line

As a new material, HDPE geomembrane has excellent anti-seepage, anti-corrosion and good chemical stability, and can be processed according to the actual engineering needs, It has been widely used for seepage prevention of dykes, dams and reservoirs in water conservancy projects, and also used as anti-seepage, anti-corrosion, leak proof and moisture-proof materials in channels, reservoirs, sewage pools, swimming pools, housing construction, underground buildings, garbage, etc. The technology has been widly ued in developed countries since 1930.

Producttion Flow:

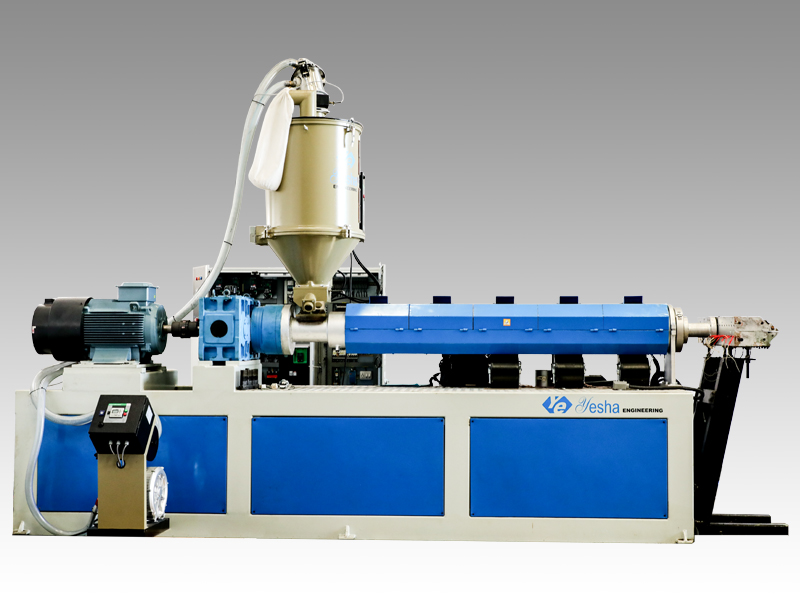

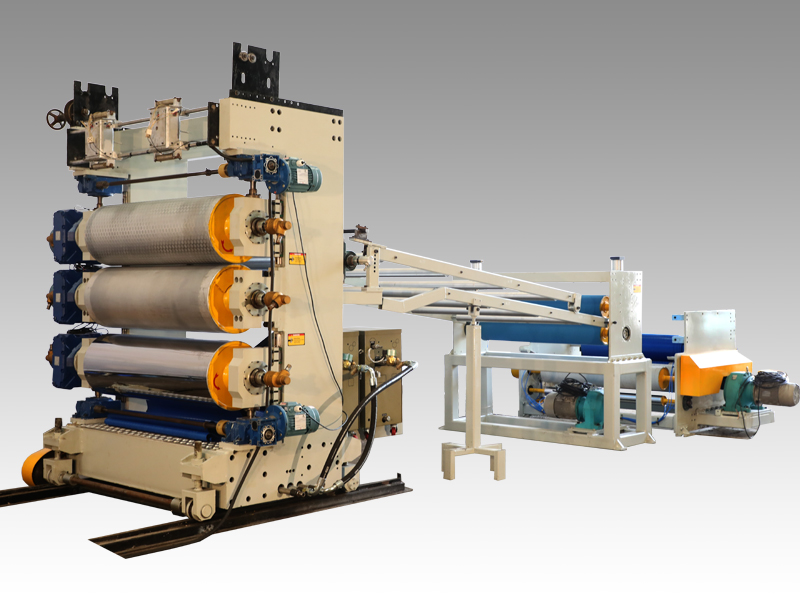

Automatic feeding unit–Extruder melt–Filter–T-Die–Three roller calender unit–Cooling frame–Hual off and trimmer–Accumulator–Pulling–Winder

PE Extra-width Geomembrane/Waterproof Roll Extrusion Line is mainly used to produce three-layer composite plastic wide anti-seepage membrane, geomembrane, and other products.

The PE Extra-width Geomembrane/Waterproof Roll Extrusion Line is mainly composed of three extruders, a hydraulic non-stop fast screen changing device, a three-layer composite head, double tuyere air ring, tractor, coiler, temperature and electrical control systems, etc. composition.

Basic Machinery Informations:

| Sheet Width | Sheet Thickness | Material | Capacity |

|---|---|---|---|

| 1000-5000mm | 0.5-3mm | PE | 500-600kg/h |

Our Clientele