Extrusion Dies - T-Die

Every T-Die manufactured by YESHA is made in accordance with the customer’s requirement.

Our engineers coordinate with the customer to comfirm the best T-Die design, try our best to help customers solve problem,for customers to create a more fit the actual production die products.

facilities established to create value for the customer-oriented business model, thinking what the customers thinking, doing what the customers urgently want. Through fast processing of all kinds of help information to carry out the full-time personnel to handle, strive to meet the needs of customers in time.

The researching and developing center of yesha which applies the actual experience to improve the application of the advanced technology. It analyze the product during the designing and acquire the design of the exact Flow of material

To guarantee the effective control over mold production schedule, delivery and smooth production without delay once customer received.

extrusion die, specializing in the manufacturing of kinds of dies for sheet, plate, film, single-layer or multi-layers co-extrusion die, feedblock, screen changer With the abundant manufacturing experience and continuously technical innovation.

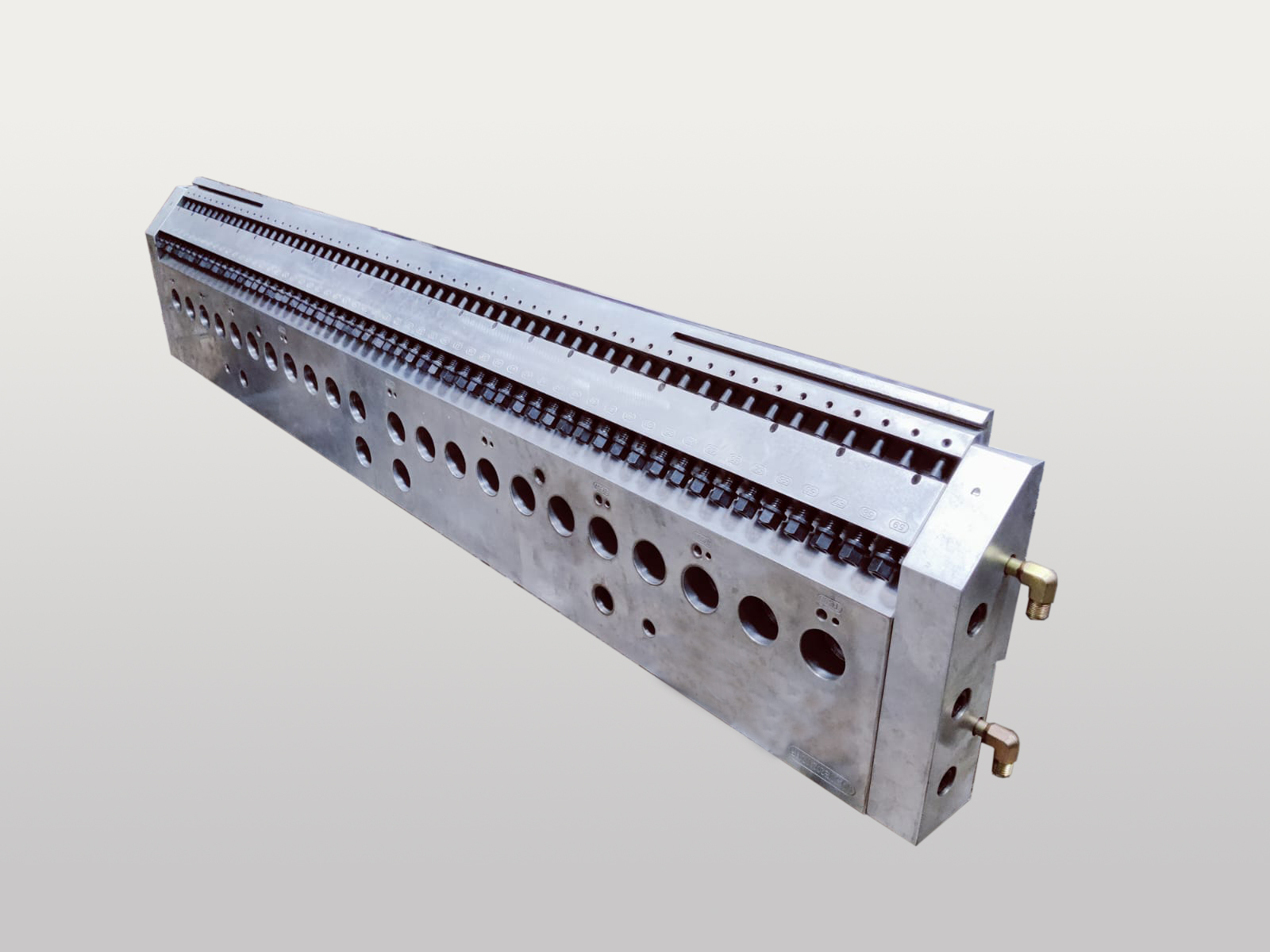

Sheet Die Upto 2000mm

INQUIRY

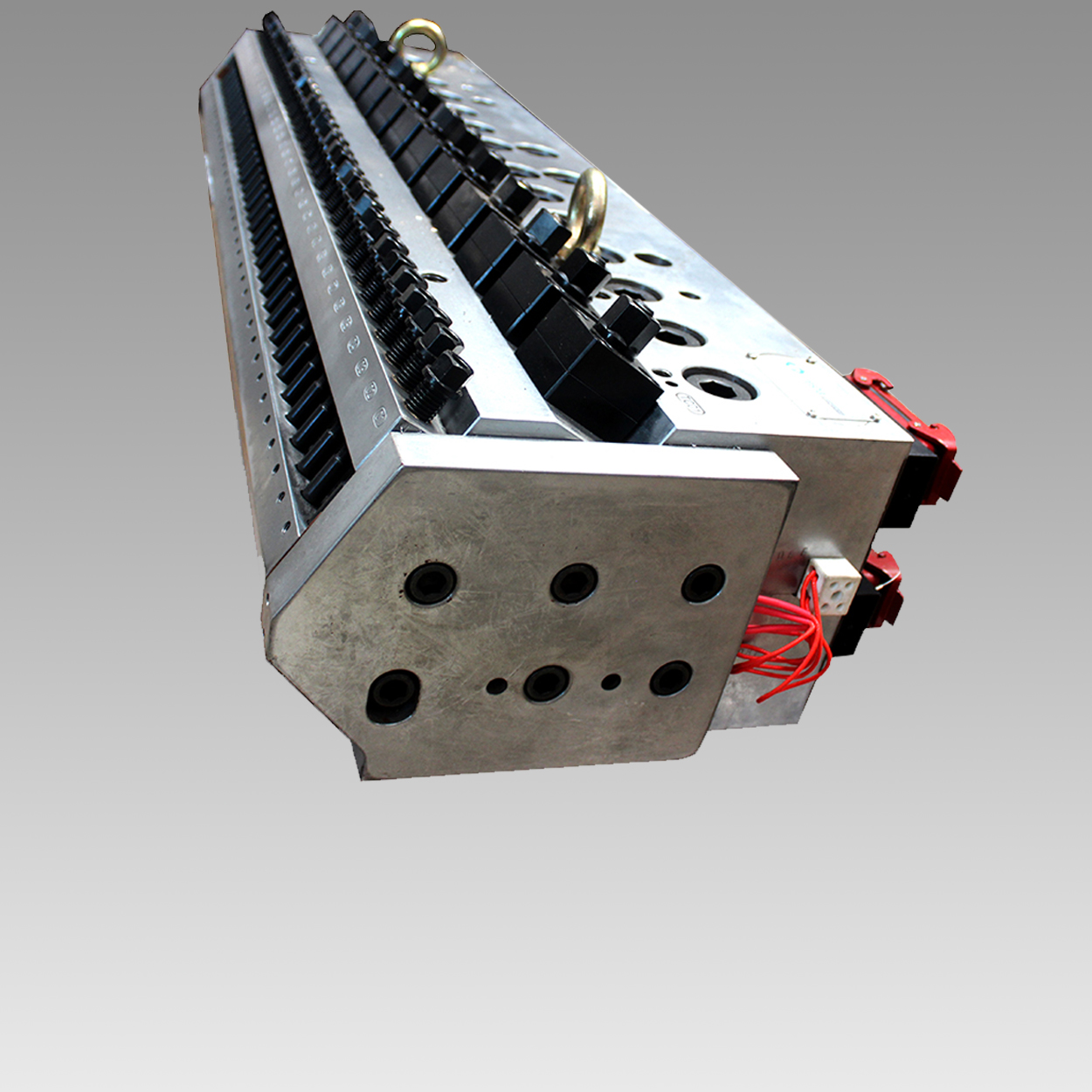

Lamination Die With Adjustable Decaling System

INQUIRY

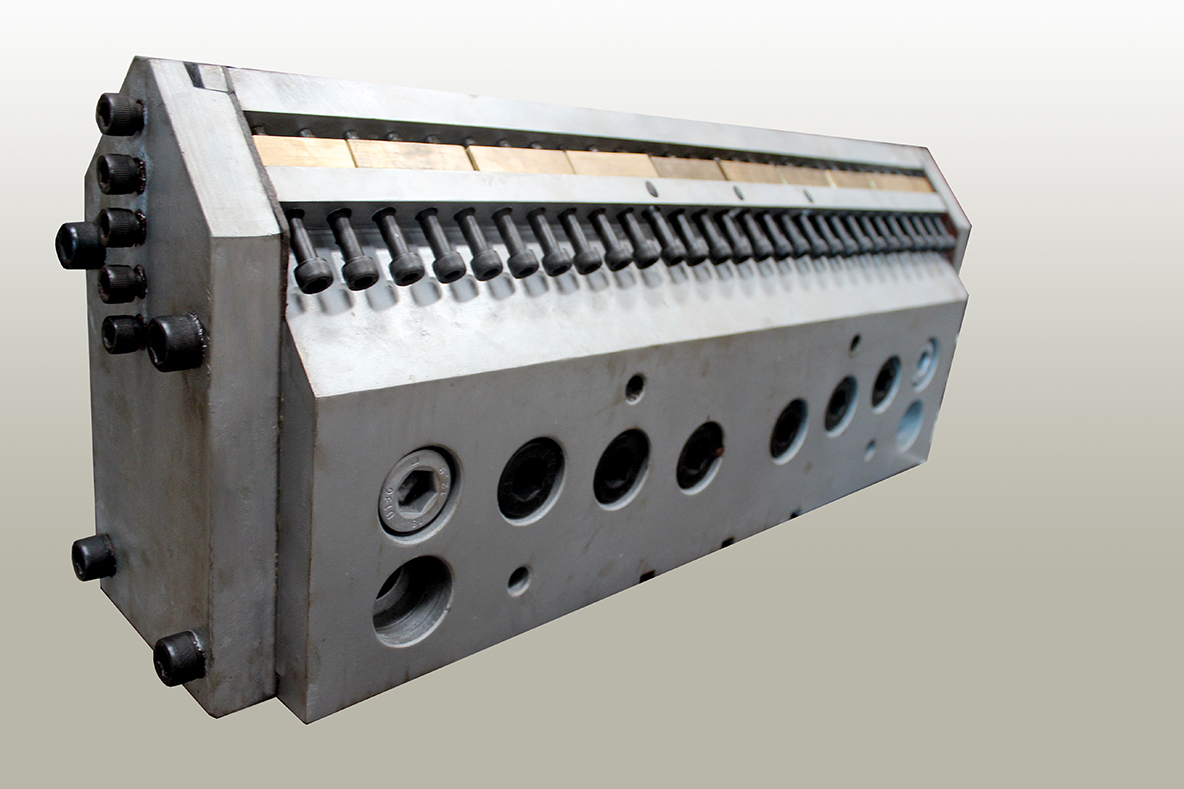

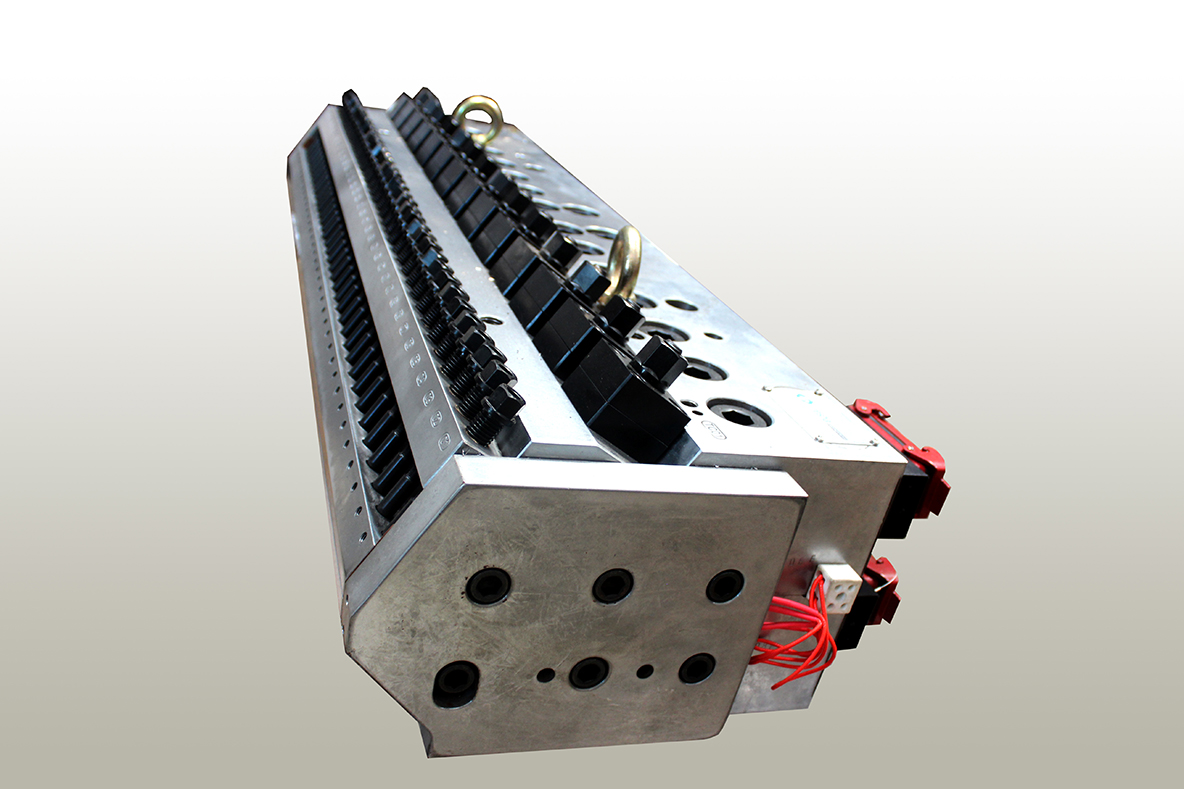

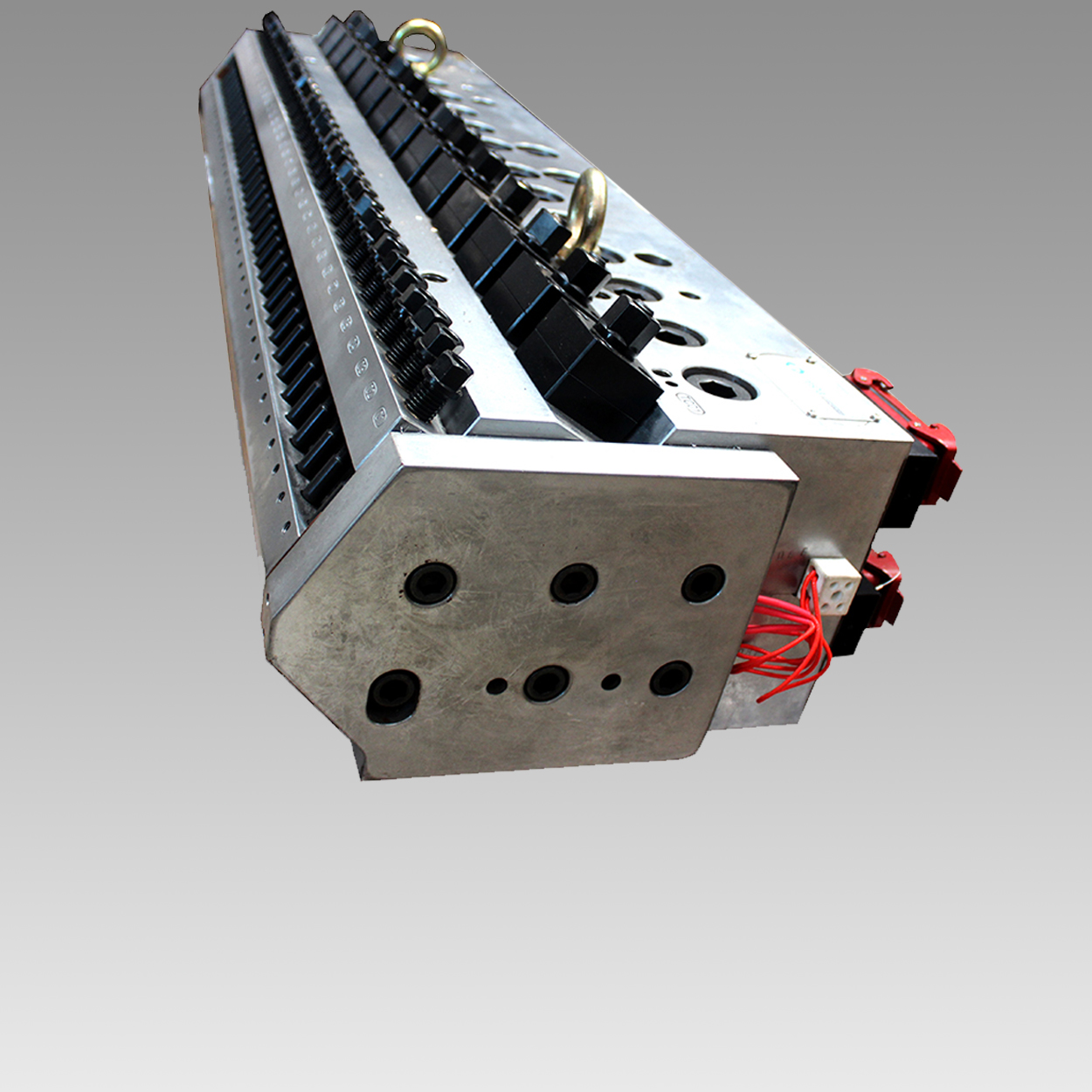

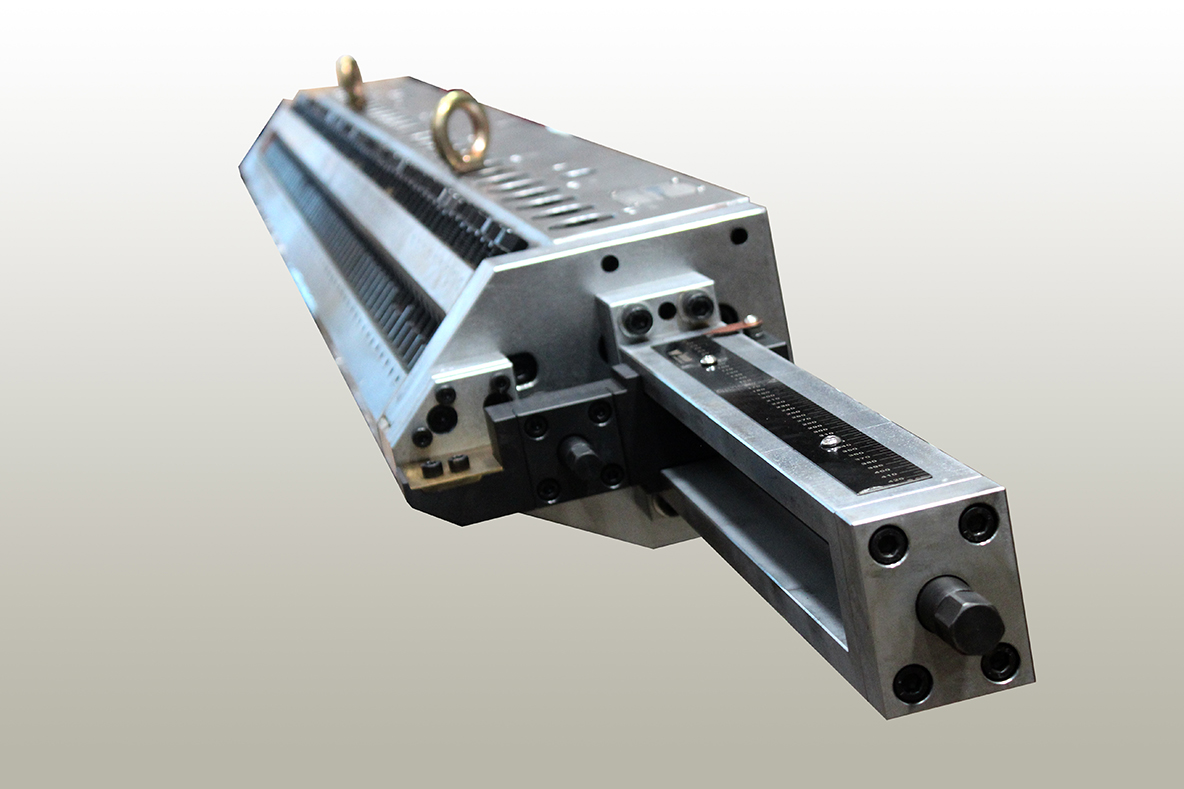

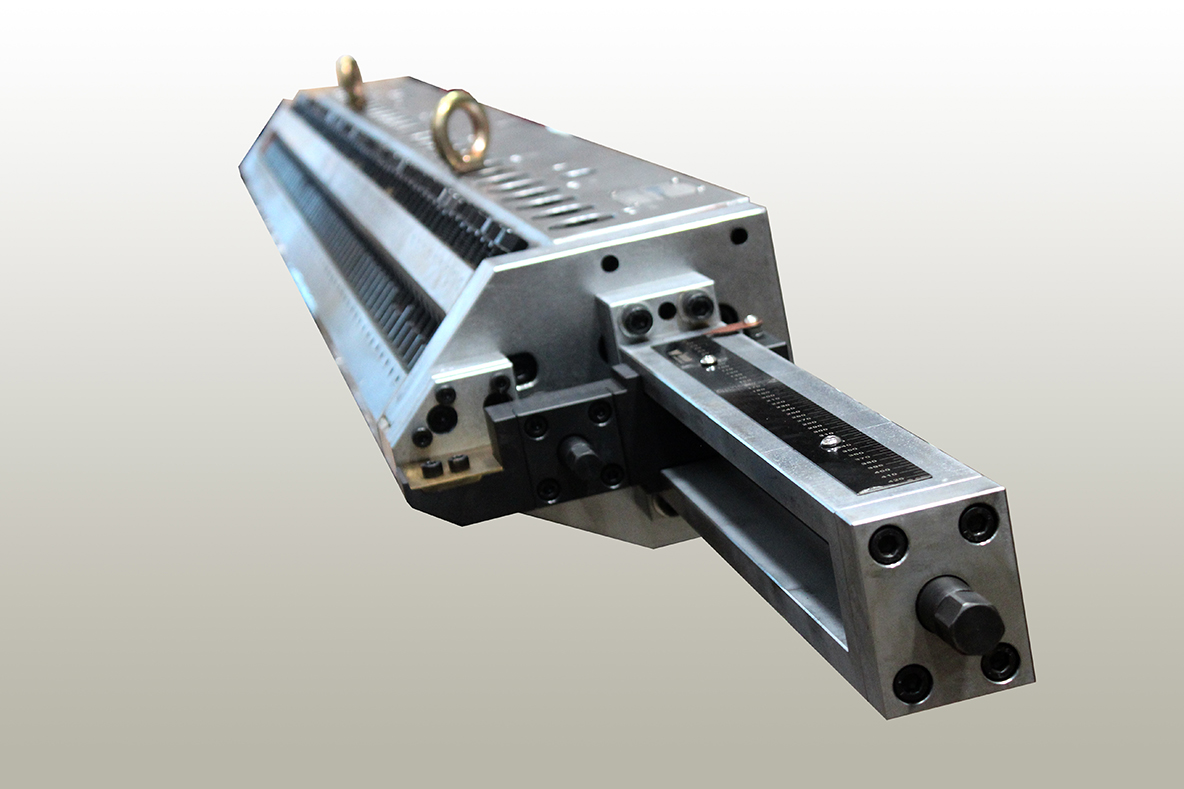

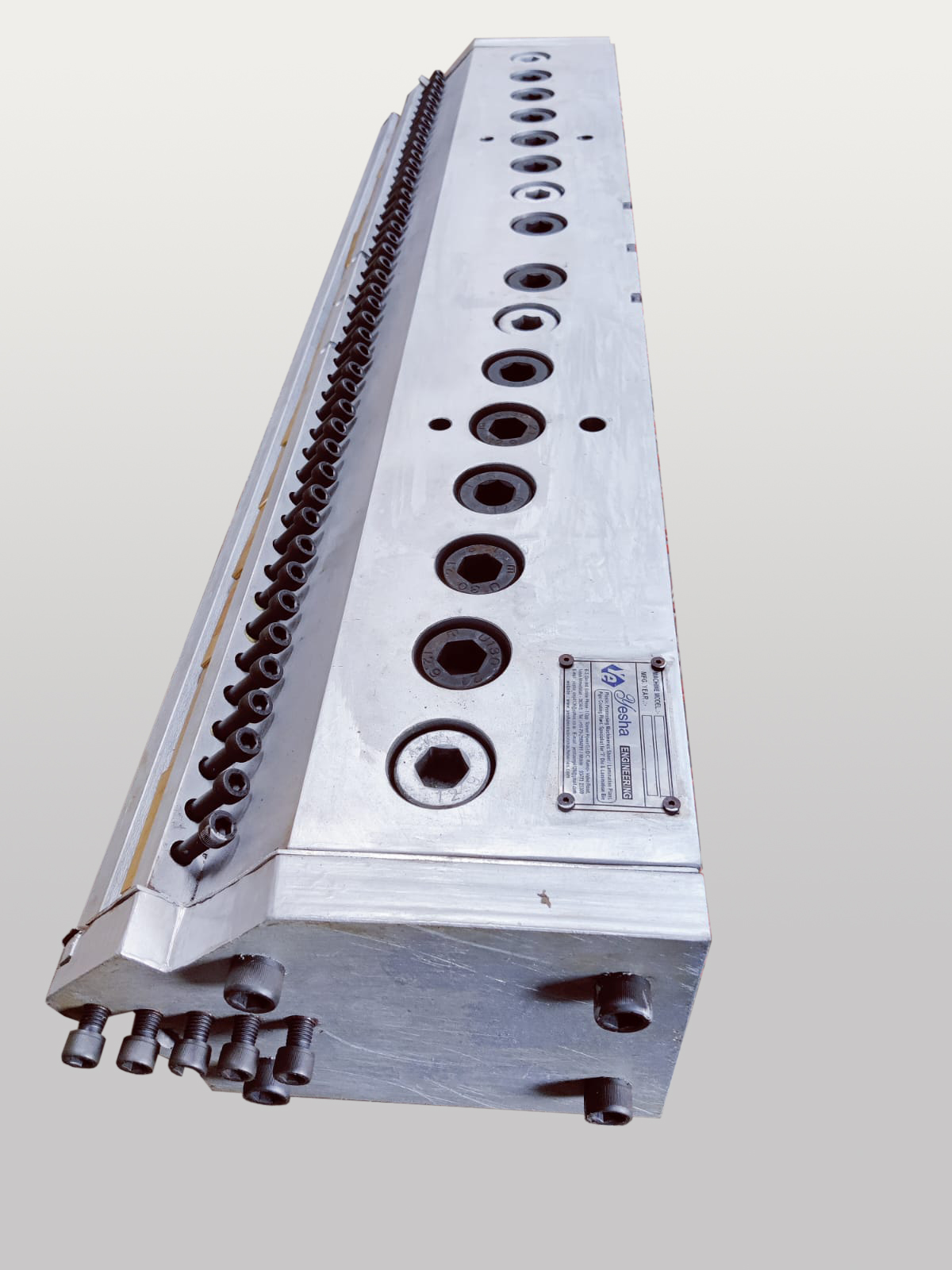

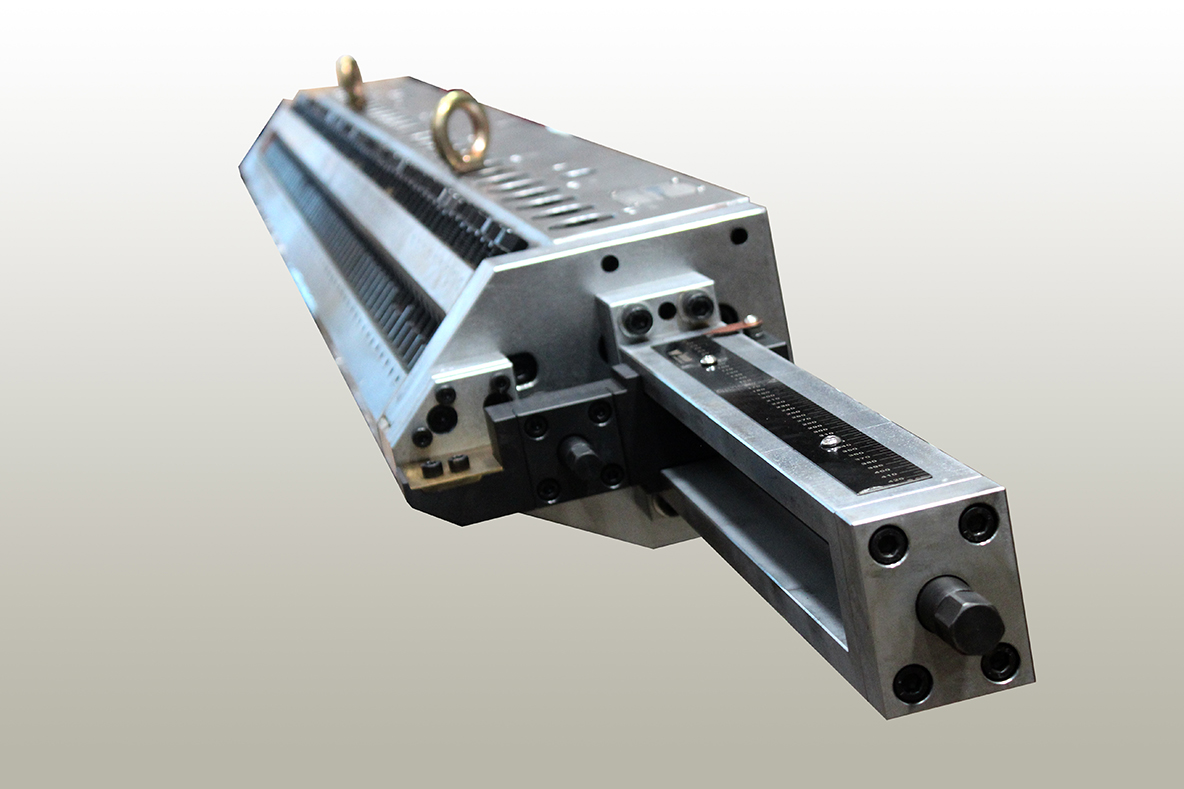

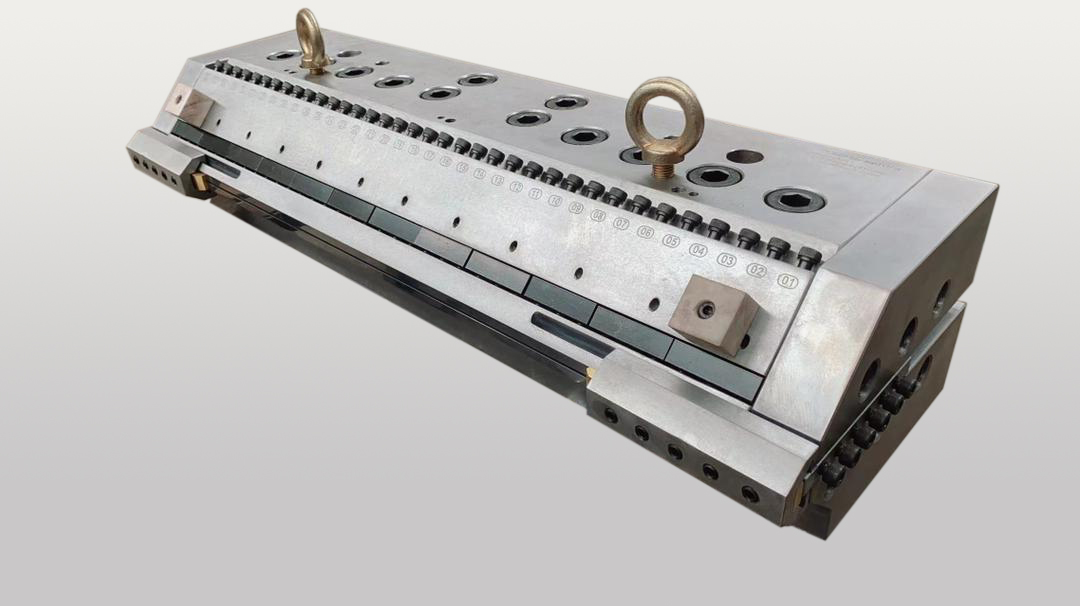

Sheet Die With Choker Bar

Lip can quickly adjust the gap for making different thickness. it is easy for adjustable. divide and extrusion can be adjusted for making different thickness products at a production line. die adopt 45 degree chock bar device to adjusting.

INQUIRY

Multi layer co-extrusion die

INQUIRY

HIPS PET Sheet Die

INQUIRY

Sheet die with cooling system

INQUIRY

PVC Flooring sheet die

INQUIRY

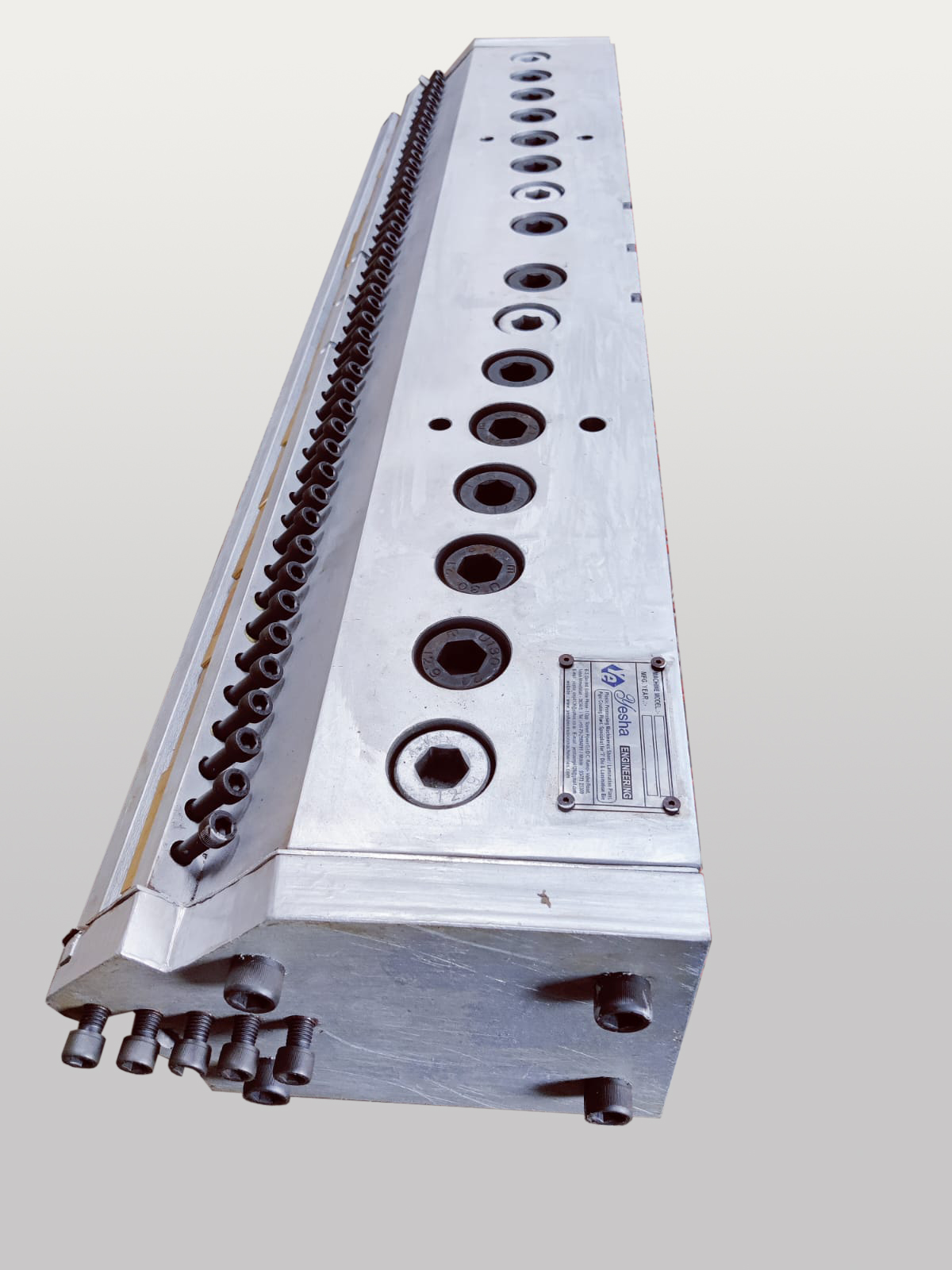

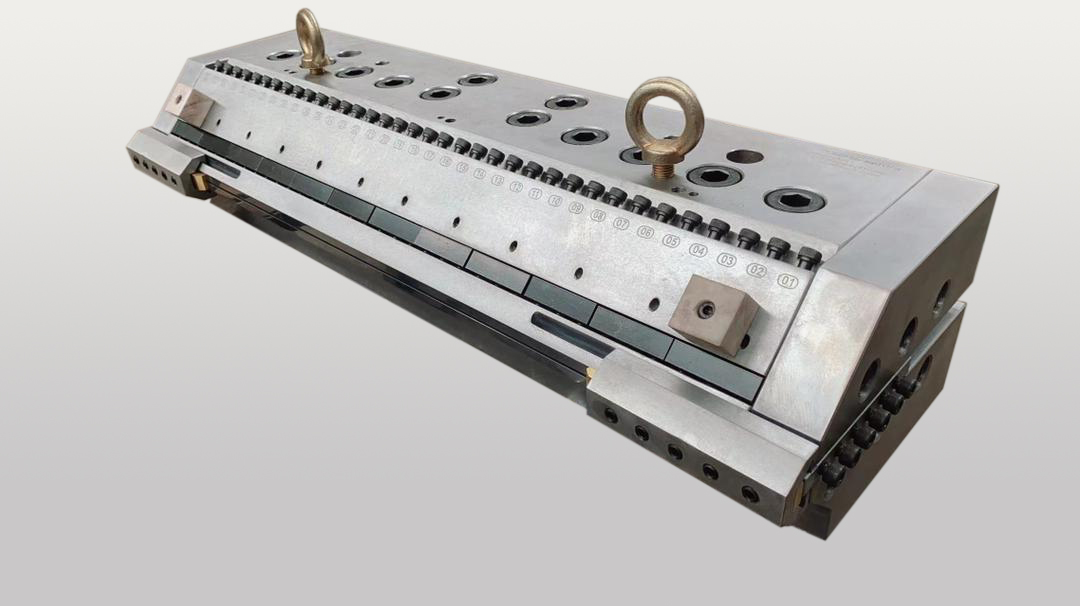

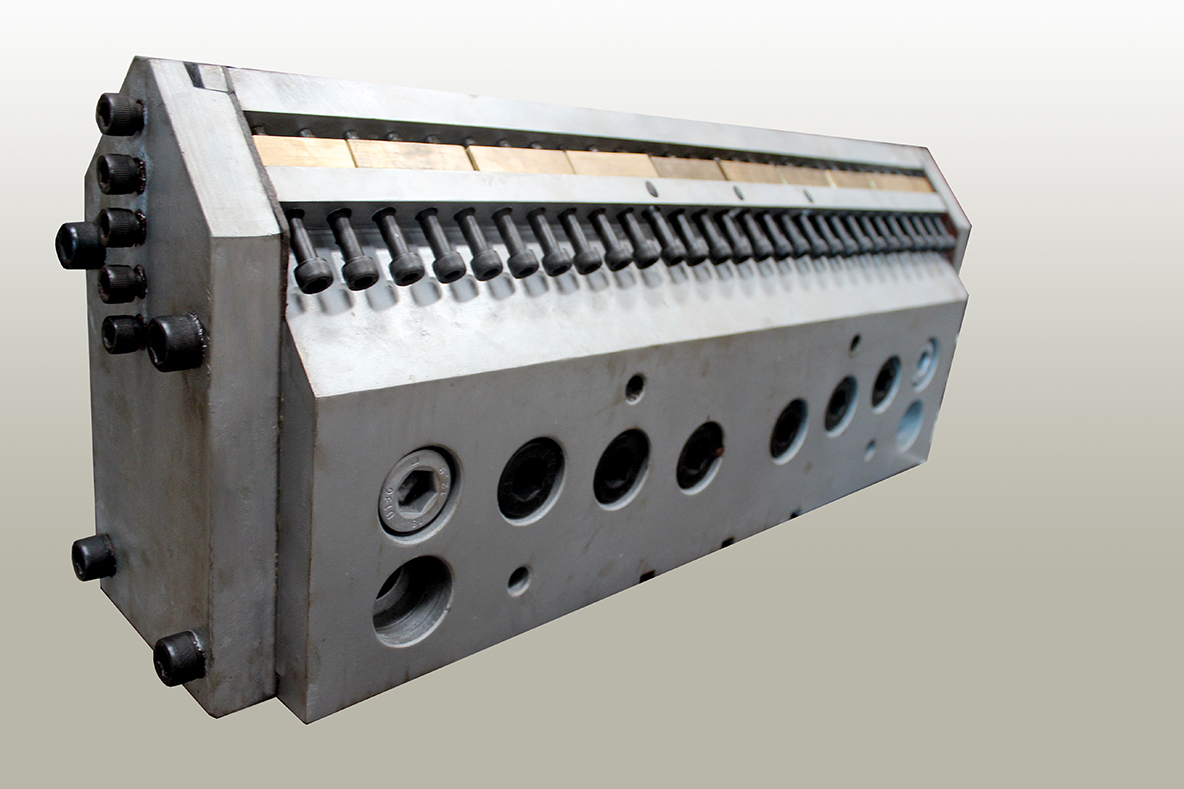

HDPE Sheet Die

Fully spaced push adjustment screw fitted with a small gap acts on the metal to bounce up and down. The die lip can be bent to adjust the die gap. Movable lower lip design to suit the different thickness requirements of extruded sheet

INQUIRY

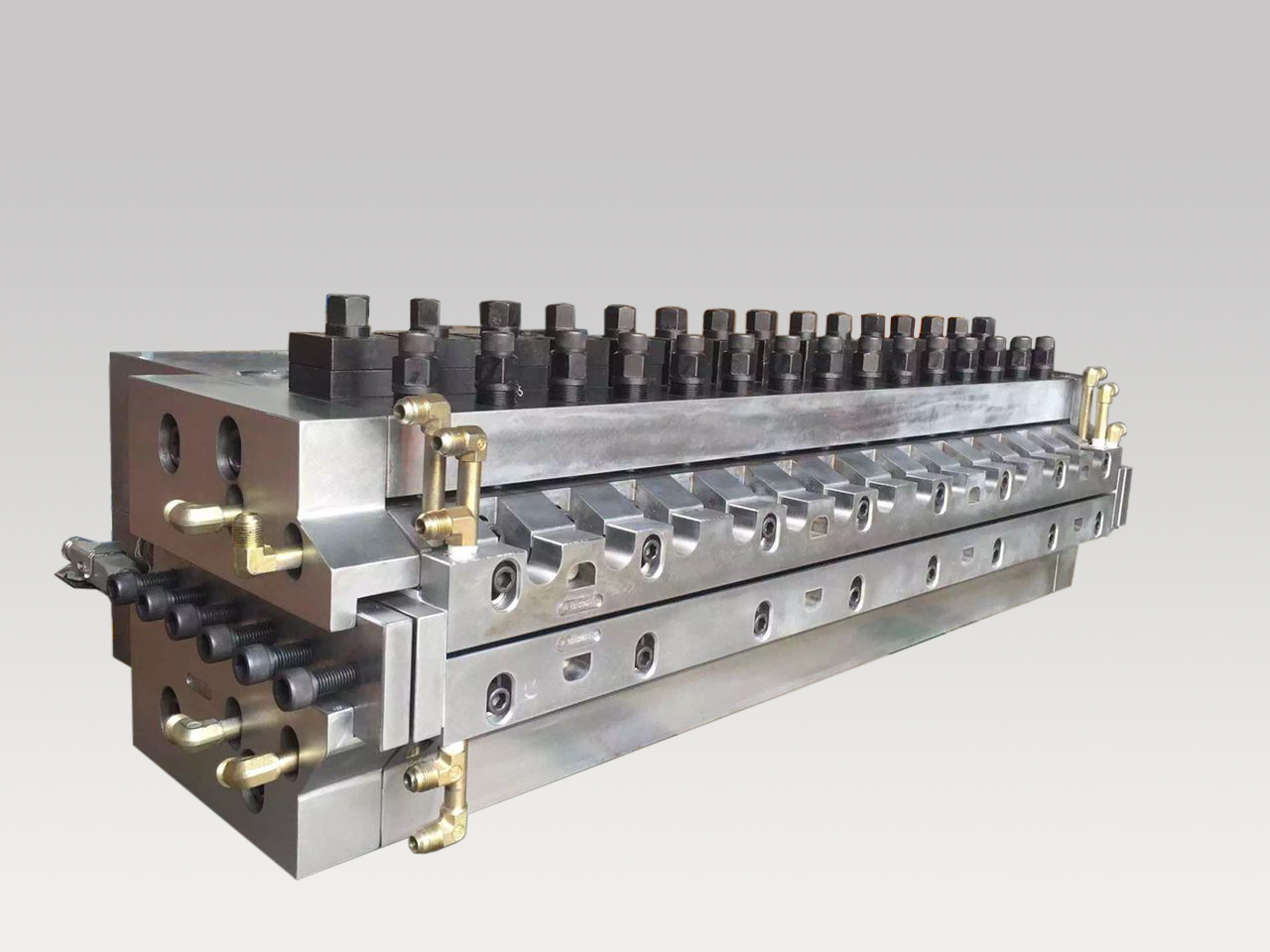

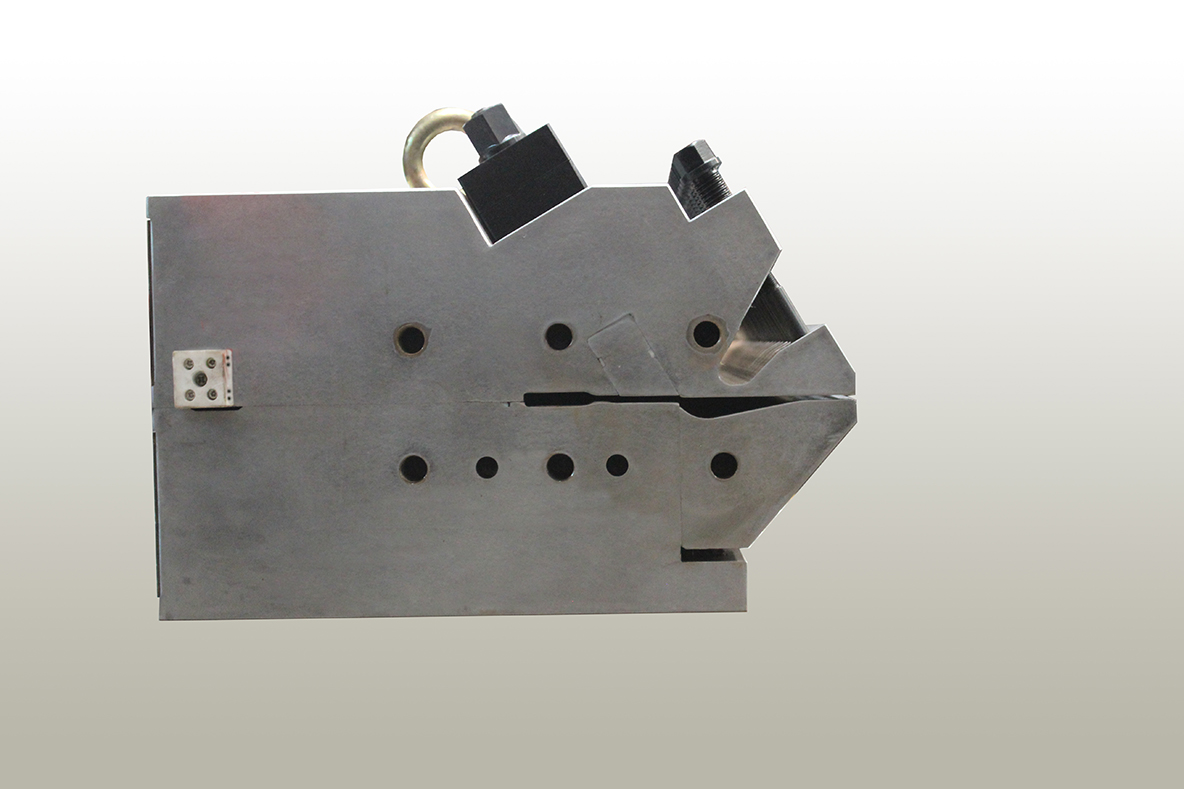

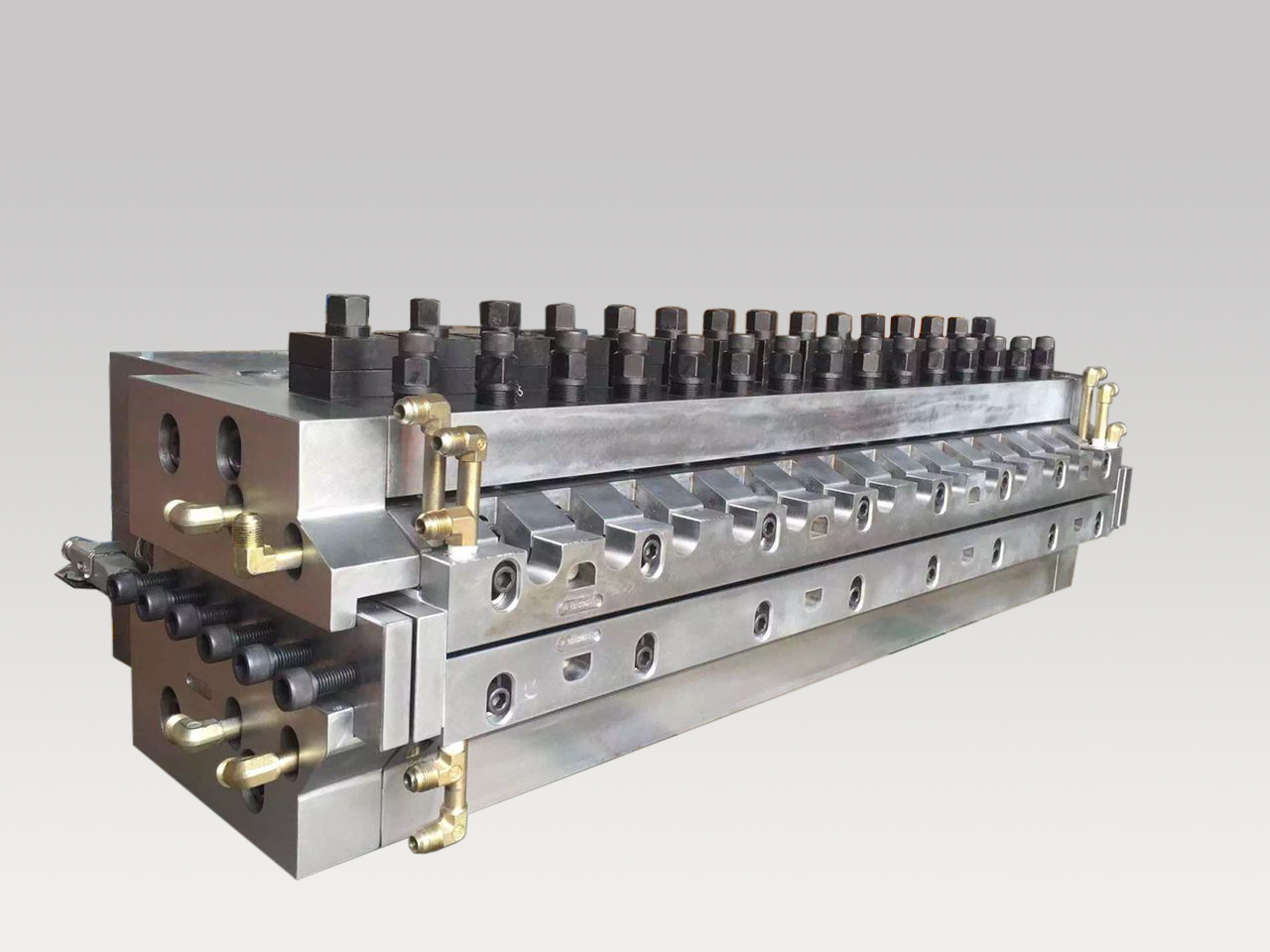

PP Board Die/ Rigid Board/Plate Die

Multiple sets of water cooling device to meet the requirements of different thickness of the product, can produce 3-30mm plate products. One set of die head can produce building templates, cabinets board, decorative panels, advertising board, furniture board, bath board, etc.

INQUIRY

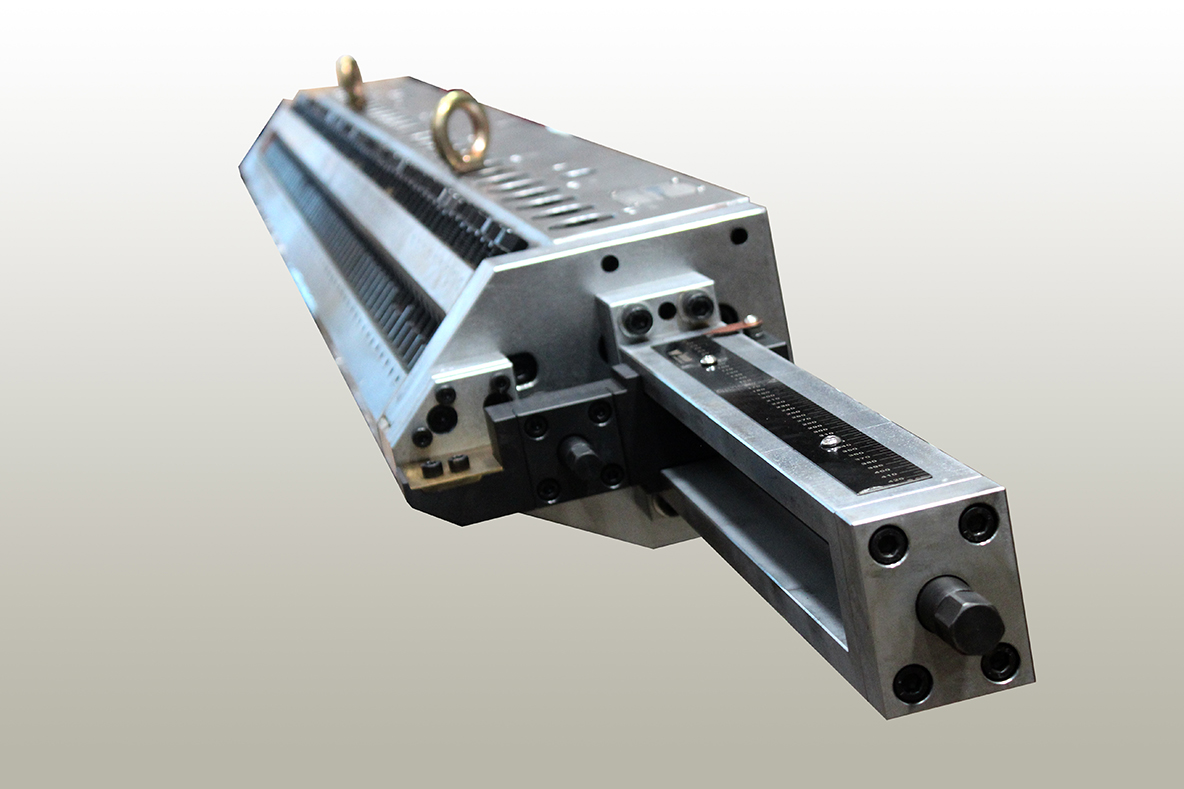

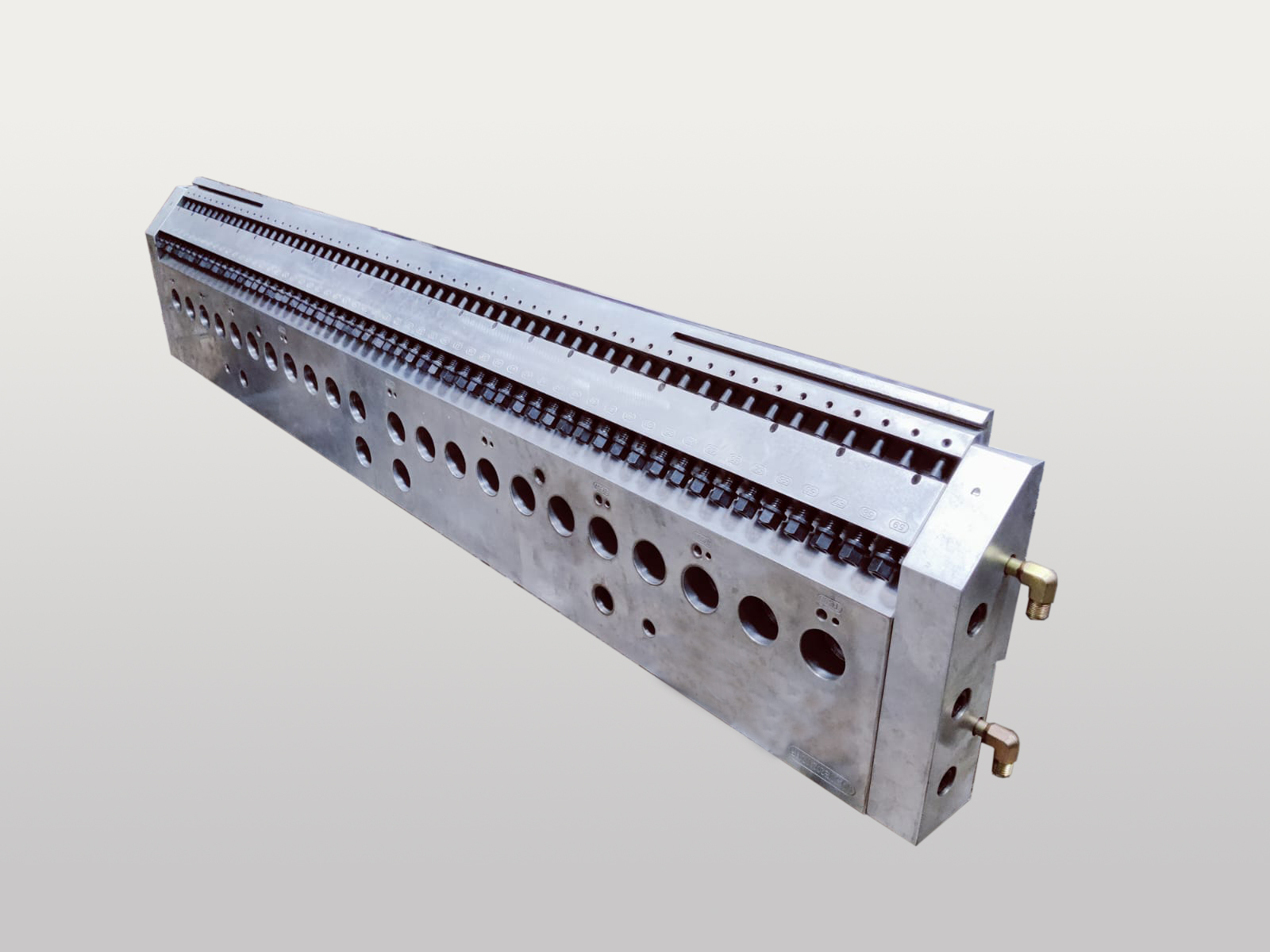

Lamination die with cooling system

The independent cooling system optimizes the response time. very suitable for production of low-temperature and heat-sensitive material. Effciently and quckliy controls product’s absolute preciseness, with telerance at ±1%, Internal ot external deckle can be equipped seiectlvely.

INQUIRY

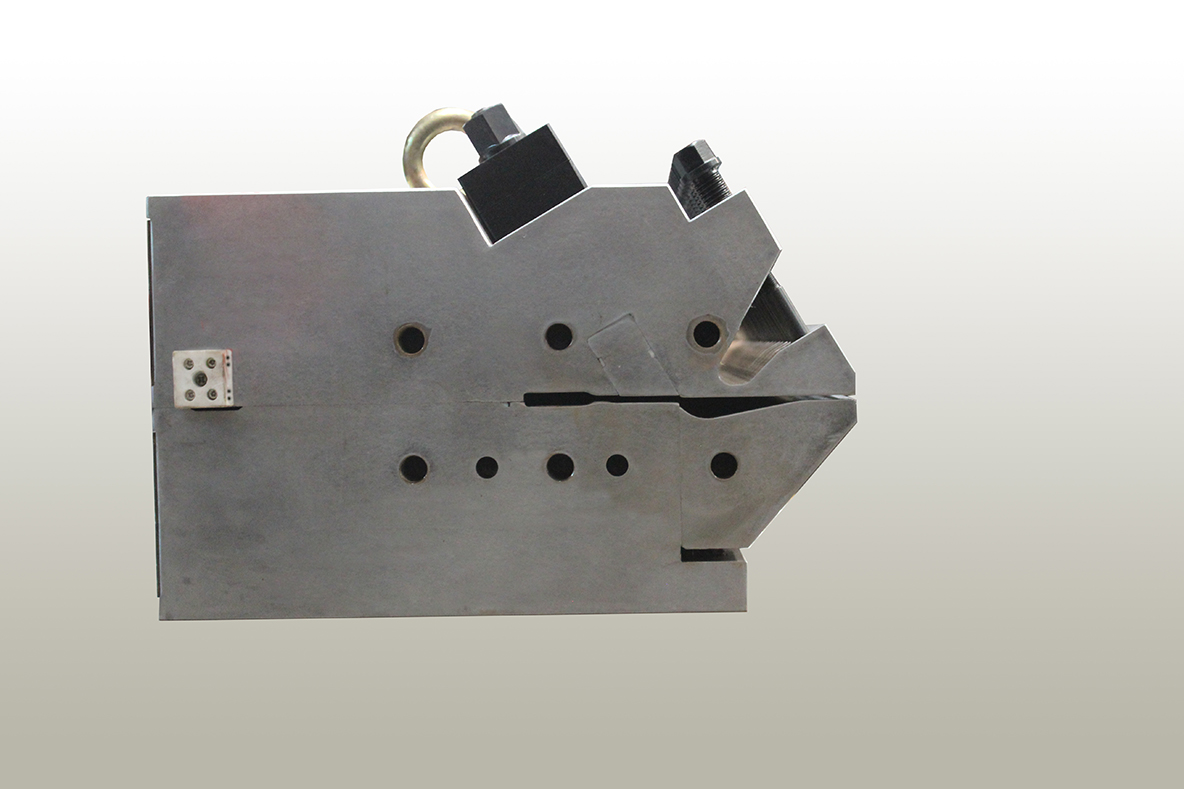

Plastic sheet die

Adjustable down lip with 90 or 45 degree restrictor bar control well meet the requirement of different thickness products. Apply to board thickness below 2-20mm.

INQUIRY

Single layer lamination film die

mostly used in lamination film production. due to its unique requirement on adjustment, mould flow channel is specially designed.

INQUIRY

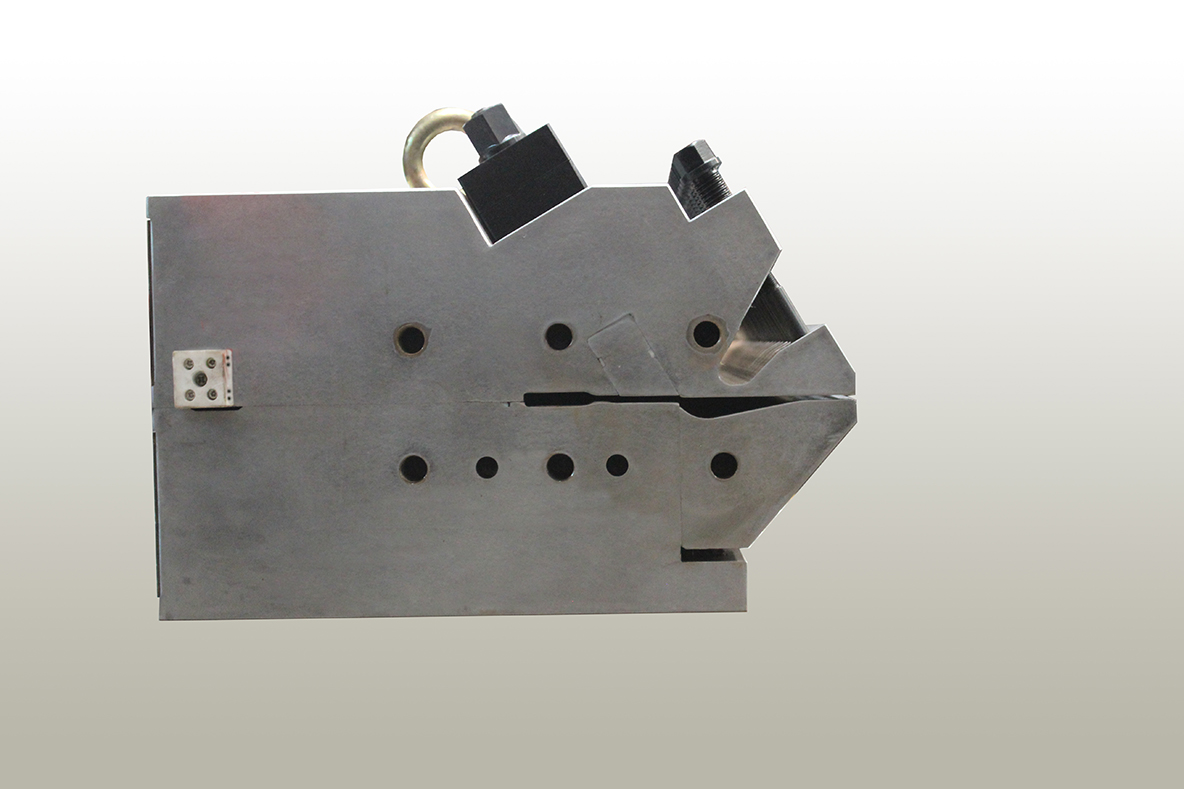

PVC TRANSPARENT SHEET DIE

Fast lip open sheet Die with super Clear & Smooth Surface,Improves the plasticization processing and Assure even thickness.

can be used to produce sheet thickness of 0.5-4 mm.

INQUIRY

Our Clientele